The pogo pin charger is considered the best compromise for electrical performance and mechanical reliability. However, for

arrays, the Pogo pin method can not achieve 50Ω contact in a region array device because it is virtually impossible to produce a

pin with a characteristic impedance of 50 W and is suitable for the currently used tight pitch.

Due to the widespread use of high current batteries in consumer electronics, engineers need fast charger solutions.

In the extensive use of portable communications equipment, regardless of Tablet PC or smart phones, because consumer

electronics products need long-term use, large-capacity batteries began to become a trend. In order to meet the long media

playback time, Tablet PC panel volume is four times the normal smart phone. If you use a normal micro USB connector, the

charging time will be very long.

|

|

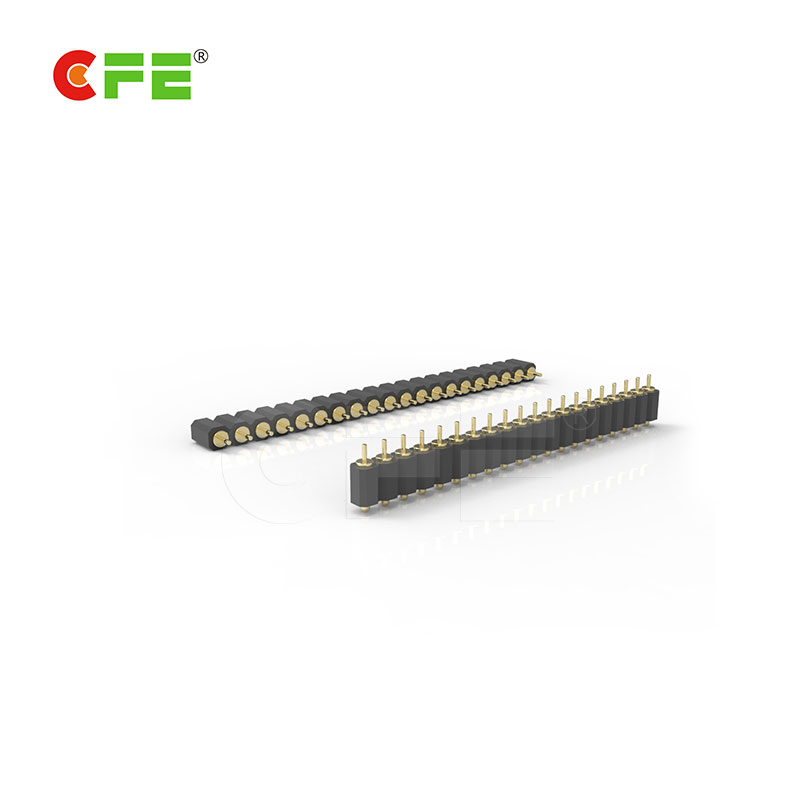

| [MP310-4122-E02100A] Though hole pogo pin electronic terminal connectors | [MP210-1144-E20100A] 2.54 mm pitch pogo pin spring battery connector |

As can be seen from the above, the traditional charger connector is not enough for new consumer electronics products, and the

cost of custom connectors is too high, this is a problem. Only the pogo pin charger connector combines the advantages of both

to become the best solution for engineers. The magnetic design provides a more user-friendly, multi-functional design that

makes the design more flexible.

Pogo Pin Charger Performance

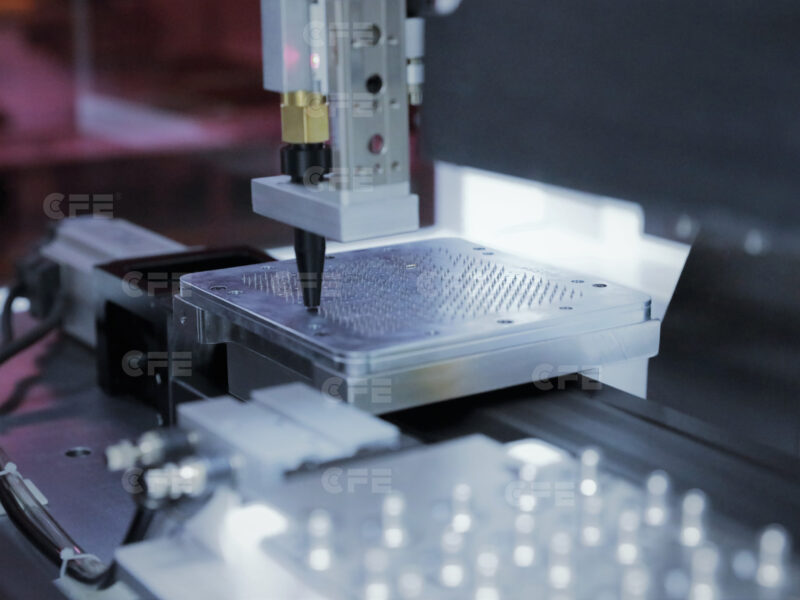

When considering the electrical performance of the pogo pin charger, an independent test laboratory should be used to

evaluate the exact configuration of the Pogo pin plan. The main values of the test are bandwidth, rise time, self-inductance,

capacitance, and mutual inductance and capacitance. Using this data, you can directly calculate the effect of the pin on the rise

time and signal attenuation.

Conclusion

Although the pogo pin charger is the first choice for most applications, the frontier application will test requirements beyond

the functionality of the traditional pogo pin charger solution. By moving to elastomers and new contact methods such as highly

conductive polymers and new solid line forms, high performance test sockets can support the performance requirements of

emerging test applications.