Pogo Pin Connector Application on Printed Circuited Board

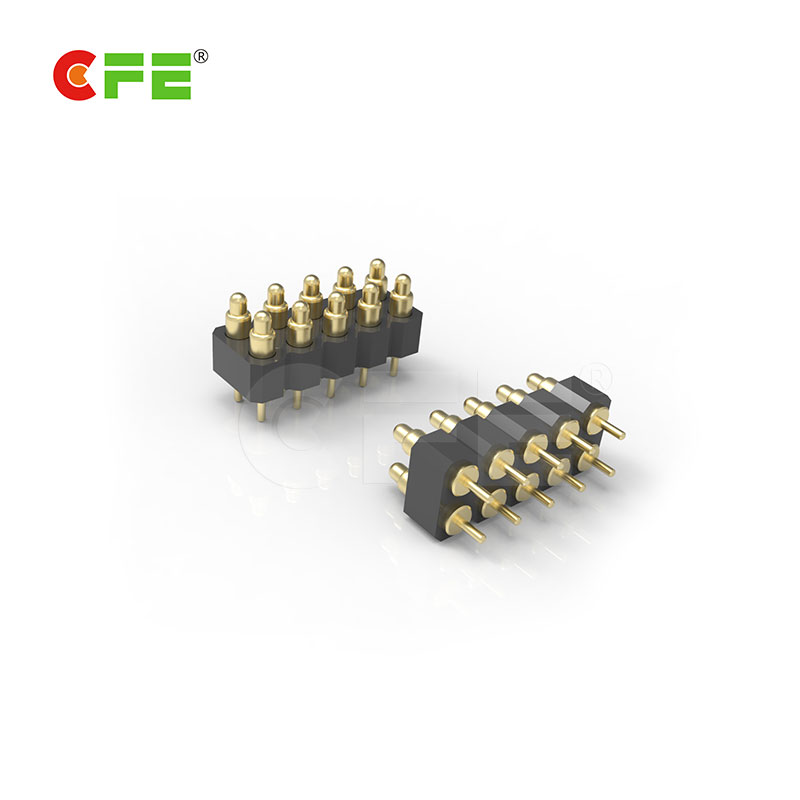

CFE implements custom connectors based on Pogo Pins and other plug technology. Due to the large number of spring contacts and even particularly small connectors, the waterproof solution (IPX6 / IPX7) and special solutions can be used for high current applications.

Pogo Pin Connector can be also divided as following categories by application:

- Data Connectors

- High-Speed Connectors

- Connectors the machine and plant construction

- Connectors for medical devices

- Connectors for measurement and control technology

- Audio Connectors

- Bus Connectors

- D-Sub Connectors

- HF Connectors

So, how can a Pogo Pin Connector works while it is used on a PCB board?

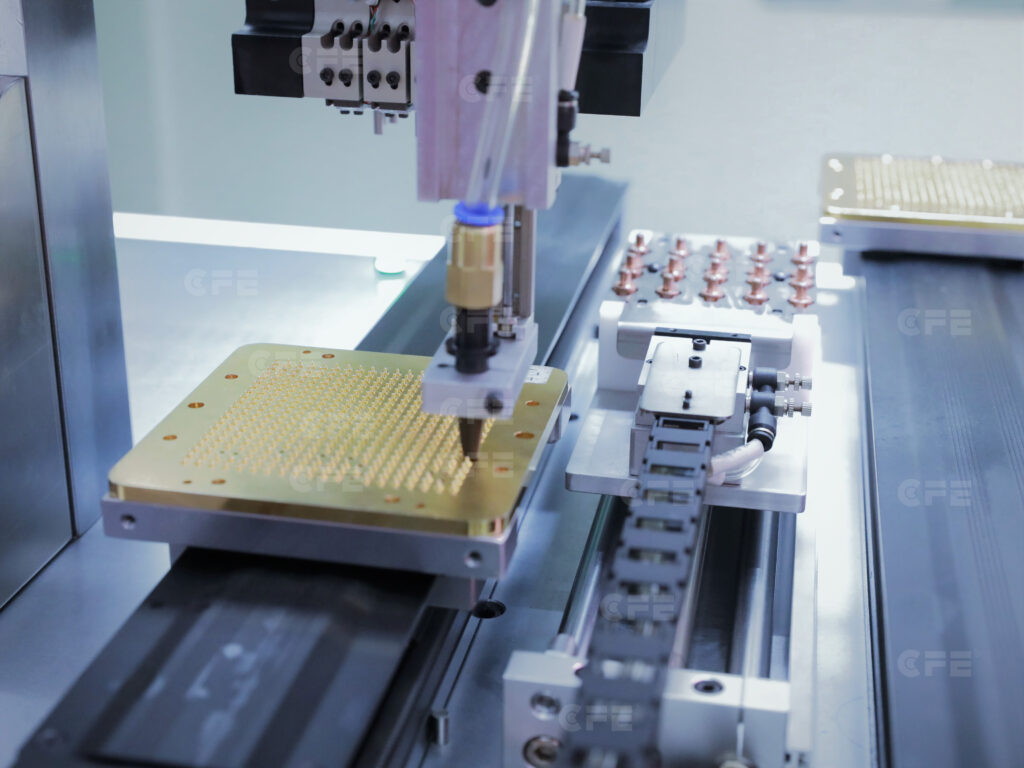

The Pogo pin can be soldered to the PCB and includes any desired circuitry. When the Pogo pin is soldered to the PCB, then the wire is soldered directly to the Pogo pin. This is actually difficult to assemble because when you heat the Pogo needle, it also heats it in place to solder it in place. It looks ugly and sometimes badly connected.

|

|

| [MP210-1111-A07100A] 7 pin through hole pogo pin connector | [MF300-3111-010001A] 2.54 mm pitch spring loaded electrical contacts connector |

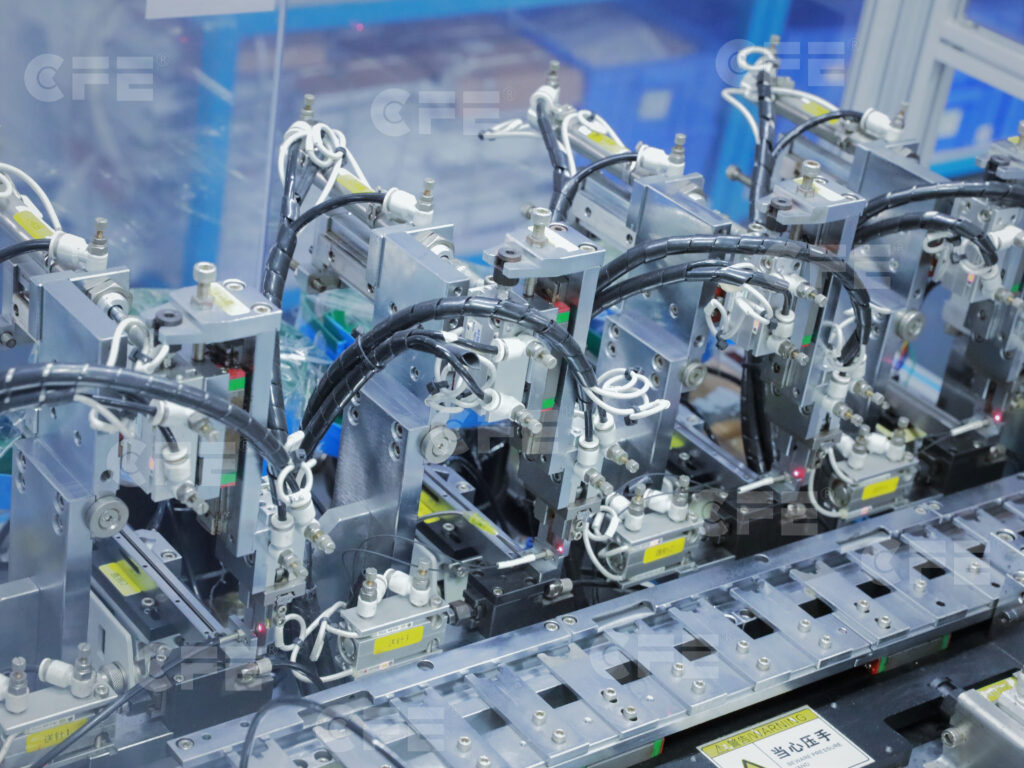

To position the development board on the Pogo pin, you can use a well-designed 3D print stand to connect to the fixture PCB. This bracket also prevents side loads on the Pogo pins to prevent them from stuck.

- Pogo Pin Connector for MP3 PCB

- Pogo Pin Connector for Telephone PCB

- Pogo Pin Connector for GPS PCB