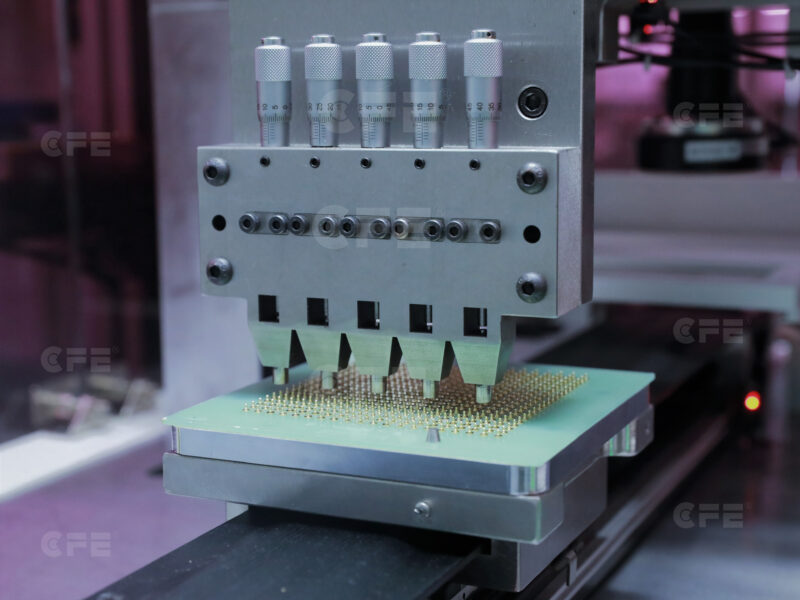

Structure of Spring Plunger

This type of industrial product uses a threaded housing and a spring loaded plunger pin assembly to close the spring. This design protects the coil while increasing the overall strength and stability. The spring loaded plunger pin and housing design allows these industrial equipment supplies to exceed the standard components by producing precise end forces with positive and controlled tension. It is time that spring days are tense and are being fired in the room.

The spring loaded plunger pin assembly comprises a polymer, typically a nylon locking element, which holds the plunger in place. The coil is connected to one end of the plunger and the other end allows adjustment of the coil movement. This setting prevents lateral movement, similar to axial bearings, to prevent damage and poor operation while ensuring reliable linear motion. During installation and repair, the tool force is applied to the housing, rather than the bare coil held by tension.

In general, this design around the coil increases the useful life of such industrial equipment supplies while providing better performance through consistent tension.

Installing And Using

Due to the use of threaded sleeve design, the installation of these products than the use of bare coil is much easier, faster. Assembly is easier to handle because the tension spring must be fixed under tension when installed. On the other hand, the spring loaded plunger pin can be locked in place.

The spring device can even be installed with a hex wrench or screwdriver, but it is best to use a specially designed spring / ball piston wrench. The right wrench will speed up already fast installation. Either way, please note that the spring loaded device is a hollow industrial product. They have significantly lower torque resistance than solid screws or bolts. When applying torque, be careful and refer to the manufacturer’s instructions. Otherwise, excessive tightening of the spring plunger may result in a sleeve catching or deformation of the component into an unusable shape.