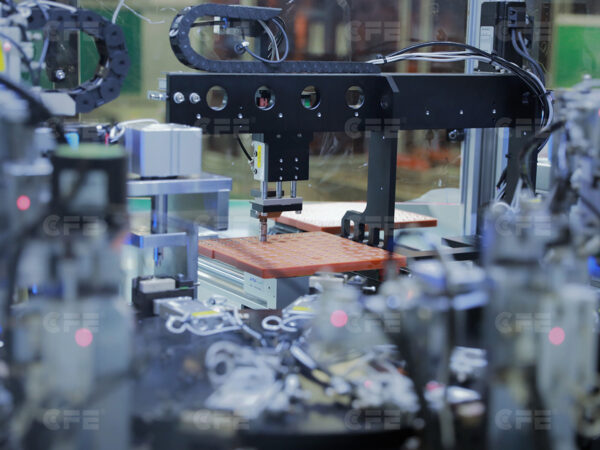

Each CFE spring loaded connectors surface mount is usually made of three machined parts and is assembled with the internal spring to provide the desired range of motion. All of these components are nickel plated with nickel to ensure excellent conductivity, durability and corrosion protection throughout the product’s lifetime. As the spring pin offers many advantages, companies in the telecommunications, military, medical, transportation, aerospace and industrial automation industries have found the advantage of using spring-loaded pins in their designs. Regardless of whether your application requires through-hole mounting, spring loaded connectors surface mount, wire terminal, press fit or alignment function, CFE has more than 100 styles to choose from to ensure that the correct spring pin is found for your design.

Spring Loaded SMT Contacts – Pogo Pins

- The spring loaded connectors surface mount can be mounted with a vertical spring loaded contact pin with a free height from 2.8mm to 8.2mm

- Selection of through-hole nails – can be used for electroplating through-hole welding, or only as SMT position nails

- Select 2, 3, 4 or 5 contact configurations for multi-contact connectors

- Round contact with gold to finish minimal wear

- Some of the options available in the Tape and Reel Kit are for automatic assembly systems

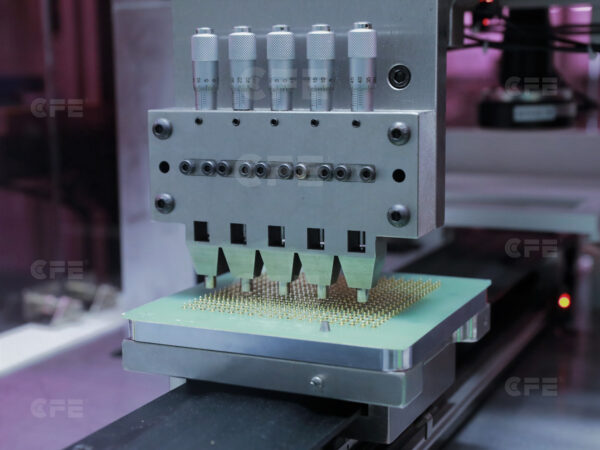

SMT Connectors

- The multi-purpose planar contact pad is used for spring loaded connectors surface mount – the thickness is between 0.1 mm and 0.5 mm

- Available in a tape-and-roll package for automatic assembly systems

- Gold-plated maximum wear resistance

- Selection of contact pad shape – square, round or oval