Pogo Pins

The Pogo pin is considered the best compromise for proper electrical performance and mechanical reliability. However, for arrays, the pogo pin method can not achieve 50Ω contact in a region array device because it is virtually impossible to produce a pin with a 50 W characteristic impedance and is suitable for the tight spacing currently in use.

Contacts

For area array devices such as BGA, QFN or LGA, it is not possible to manufacture 50Ω coaxial contacts at a necessary spacing of 0.4 to 0.65 mm. The solution to the problem is to make the pogo pin as short as possible. For example, a 2 mm pin can achieve a lower parasitic effect and can support 20 GHz bandwidth applications. However, at these high frequencies, mutual parasitism (L + C) will introduce excessive mutual coupling between test contacts.

|

|

| [MF513-1111] Large spring contact probes pogo pins | [MF310-1111] DIP spring loaded pins for pcb testing |

Pogo Pin Socket

From a mechanical point of view, the socket contact length should be as short as possible and the Z compliance is 0.010 to 0.030. “For BGA sockets, the socket manufacturer typically uses a” floating guide “, which is a floating plate with holes allowing the ball to fall , And as a positioner for the DUT, and then compress the device to the contact. Today’s automatic processing program can accurately locate the device, so the floating plate is entering the 1.2 mm pitch device.

In the past few years, test socket manufacturers have been using double-ended spring pins for a large number of QFP, BGA and LGA package testing. These pins can be used at any pitch of 0.15 mm for CSP and KGD for a more standard 1 mm pitch for ordinary BGA packages. Devices with pins up to 3000 I / O make it easy to build sockets with spring pins.

|

|

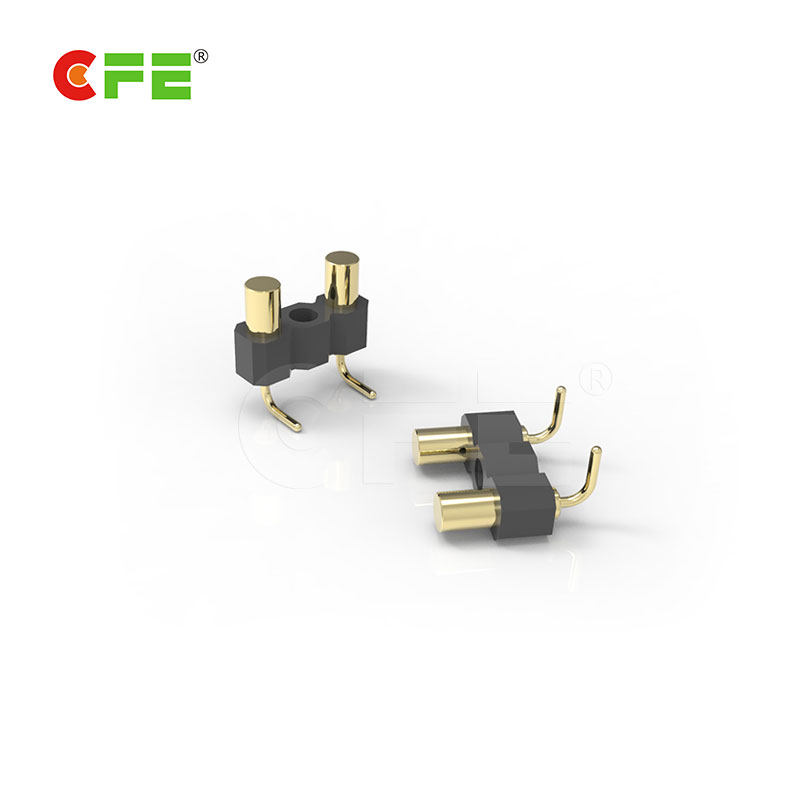

| [FF400-1120-A04100A] 2.54 mm pitch 4 pin female connector for pogo contacts | [BP84331-02254A0C] 2.54mm pitch right angle spring loaded probe pin connector |

Electrical Performance

In order to obtain maximum electrical performance and signal integrity, the contact length is usually very short. If the contact is too short, the necessary flexibility is sacrificed to accommodate the nonplanarity of the DUT package and the good oxide penetration of the package lead.

Pogo pin suppliers now offer pins for a single active plunger to reduce the total length of the pin and maintain compliance. With its sharp top plunger, the appropriate spring needle can penetrate the oxide with a very small force (<20 g) and does not damage the packaging leads / pads or balls, or leave unnecessary “witnesses on the DUT “Mark or PC board. 40 to 60 g of force often leaves a traces of witnesses that could lead to early failures in contact with the board when welding is in place.