Bending 40pin-128pin Pogo Pin Connector with Housing, Right Angle Spring Pin Connector,CFE Electronic spring loaded connectors,Over 14 years’ experience in manufacturing pogo pin connector,and we own 12 items national patent of spring contacts

CFE Top Strength

- Over 14 years’ experience in manufacturing pogo pin connector,and we own 12 items national patent of spring contacts .The highest life test has up to1000,000 cycles, can custom various shapes,small structure and high current (2-20A).

- Our factory has been accredited the ISO9001:2008,ISO14000 certificate,spring loaded connector accord with HF,RoHS,Reach standard.

- 100% electrical test provided on function before delivery.

- We believe that: “Quality to win markets, improvement to win progress”. Welcome customers all over the world come to our factory to give guidance for development !

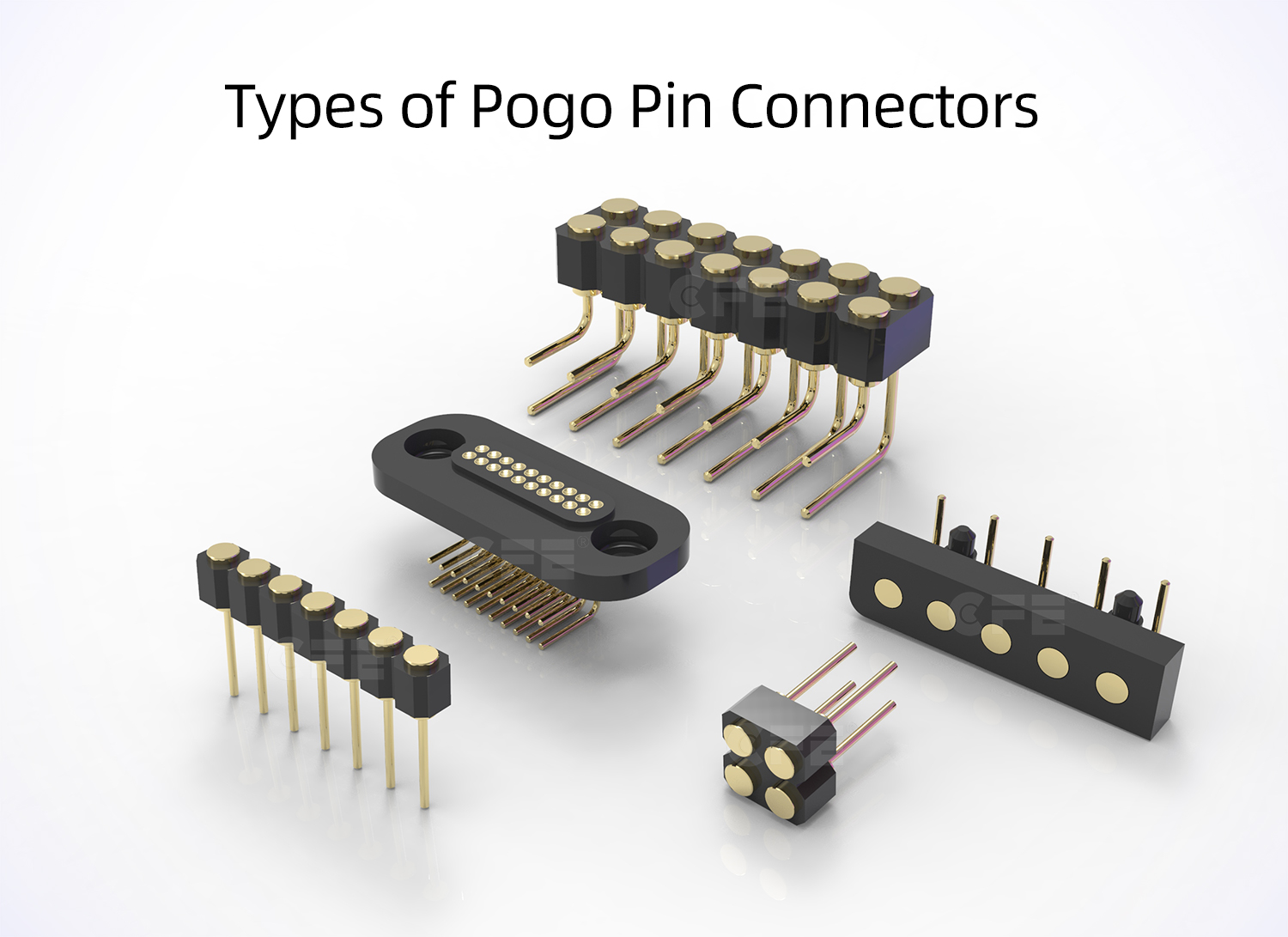

Pogo Pin Connector Strong Point:

- Customize high current charger pogo pin more 1600 items(2A-20A)

- Customize Pogo pin connector more 300 items(2pin-60pin)

- Development 1.27Pitch 2-40pin standard products(6mm-15mm pin’s length)

- 2.54mm pitch, 2-40pin standard products,housing height 1.27mm

- Development 2.54pitch 2-128pin male & female pogo pin connector(4.5mm-15mm height)SMT/DIP(Through-hole)/Right Angle/Solder Cup Type

Learn more 2.54MM Pitch Right angle Pogo Pin Catalog

Specification of Right angle pogo pin connector

| Pogo pin connector | Data |

|---|---|

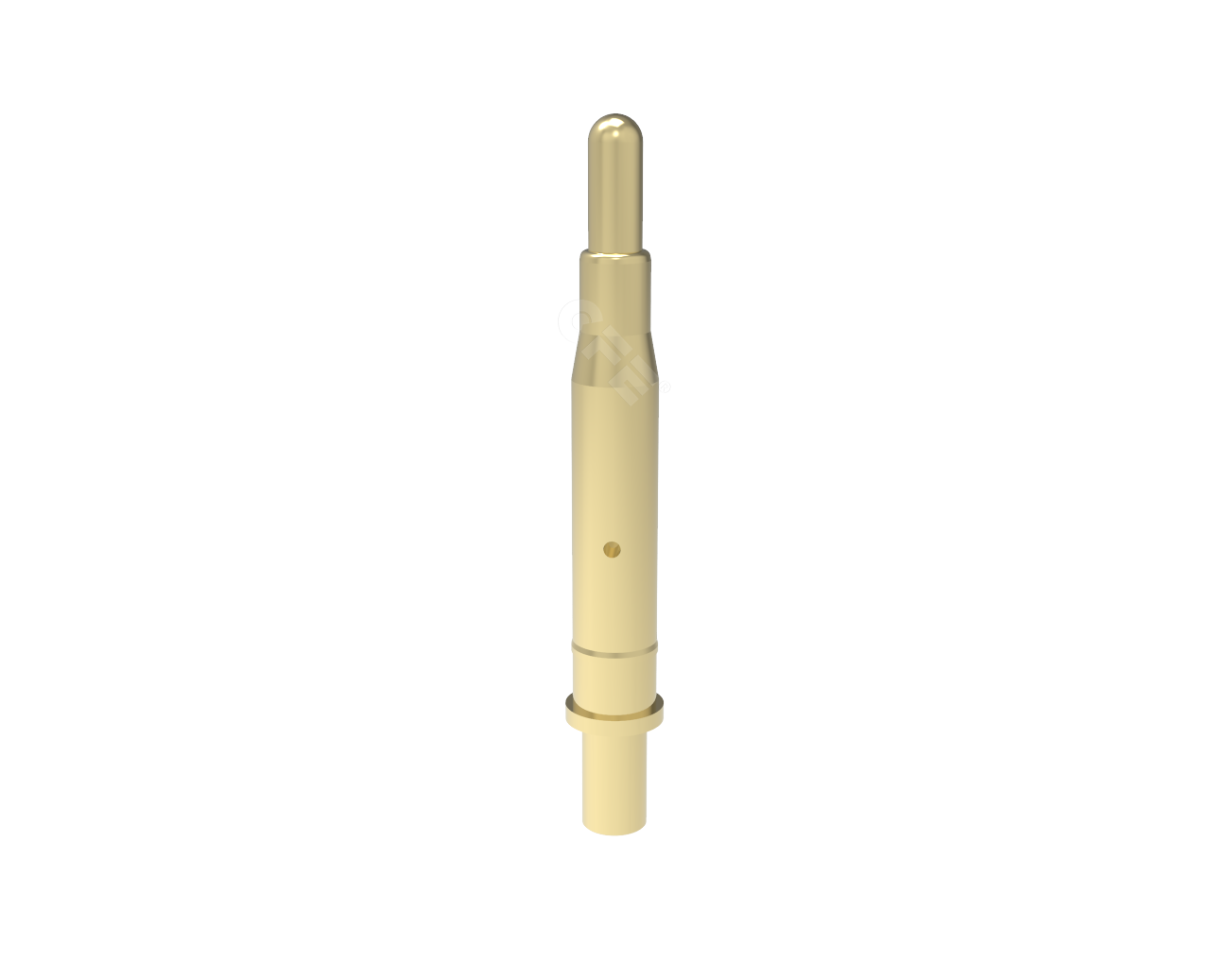

| Materials & Plating | Barrel:Brass,Beryllium copper,Phosphor Bronze |

| Plunger:Brass,Beryllium copper,Phosphor Bronze | |

| Spring:Stainless steel,Music wire | |

| Plating:Gold,Silver,Palladium-Nickel | |

| Flammability: UL94 V-0 | |

| Insulator:HTN,LCP,PBT | |

| Technical Specification | Rated Current:1A-20A(different structures) |

| Rated Voltage:AC/DC 12V | |

| Contact Resistance:50mΩ Max. (stillness, Working stroke) | |

| Operating Temp.-40°-+85° | |

| Life test:100,000 ~1,000,000 cycles | |

| Reflow Temp.265°, 4~5sec | |

| Environmental Test Standards | Salt spray test EIA-364-26 method B.Ka:48h |

| Humidity test EIA-364-31B method Ⅱ condition A, 96h | |

| Temperature cycling or thermal shock test EIA-364-32D method A condition 8:-40°-105,Five cycle | |

| Temperature life test EIA-364-17B method-A condition-3 condition-A: 85°,96h | |

| Vibration test EIA-364-28E condition-Ⅱ,10~500Hz,10g acceleration shock time:15 minites |

|

| Mechanical shock test EIA-364-27B condition-A: 50g acceleration, triaxial six sides, each axis three times | |

| Resistance to solder test EIA-364-56C condition-D level 2:260° 20s | |

| Solderability test EIA-364-52: 245°, 5s | |

| Certifications | ISO9001:2008,ISO14000 |

| ROHS,Reach,HF standards |

Pogo Pin Connector Application

Pogo pin Connectors developed & produced by CFE, can be applied to unlimited applications.

Below are just some of the examples of how the products can be used Please feel free to contact CFE for more details

- Consumer electronics products,PCB board

- Digital camera/Medical products/ Printer cartridges

- Golf handle/ Electric vehicles/ Telephony applications

- Cardiac defibrillator/Car charging /Air purifier

- LED flat luminaries/LED flash light/Tablet/Laptop/PC

- Power bank/ Digital product/ Small household electrical application

- Charging products/Signal transmission products etc

The Best Service Comes From

- Quality and Performance

- Reliability and Durability

- Competitive Price

- Rapid Design and Delivery

- Reliable and Honest Partnership

Customized service

Learn more about How to order special pogo pin, If you have special requirements please contact us

About CFE Electronic

CFE Electronic® company has approved the certification of ISO 9001 and ISO 14001 certification. CFE has been identified as the National High-Tech Enterprise by China government in 2016. Besides these certifications, CFE still owned 25 more international and national patents. Aim to offer the best quality product for customers, CFE follows the standard of EU, ROHS, REACH, HF, and N6P.

The philosophy of our firm is : quality is the most important factor in business! Our company has established, maintained and relentlessly improved the quality management system, so as to ensure the highest quality of products and services.

For example, during the pogo pin reliability test, the product undergoes several inspection procedures, including the dynamic impedance, constant temperature and pressure, durability, temperature increase, vibration, drop test and the instant-off test, etc. This ensures your client’s product will not break down due to a pogo pin defect.

Featured products

|

|

|

|

|

|

|||||

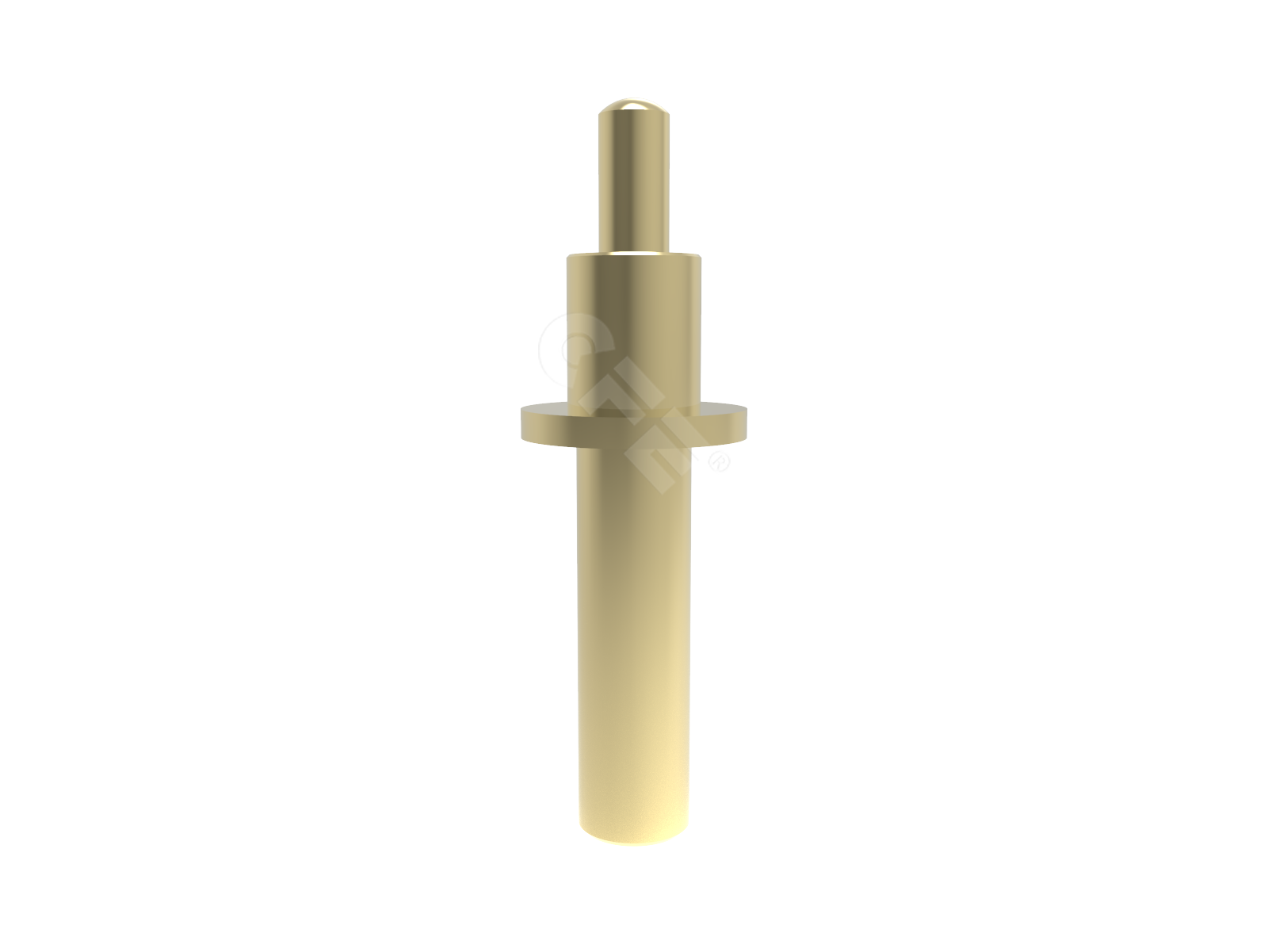

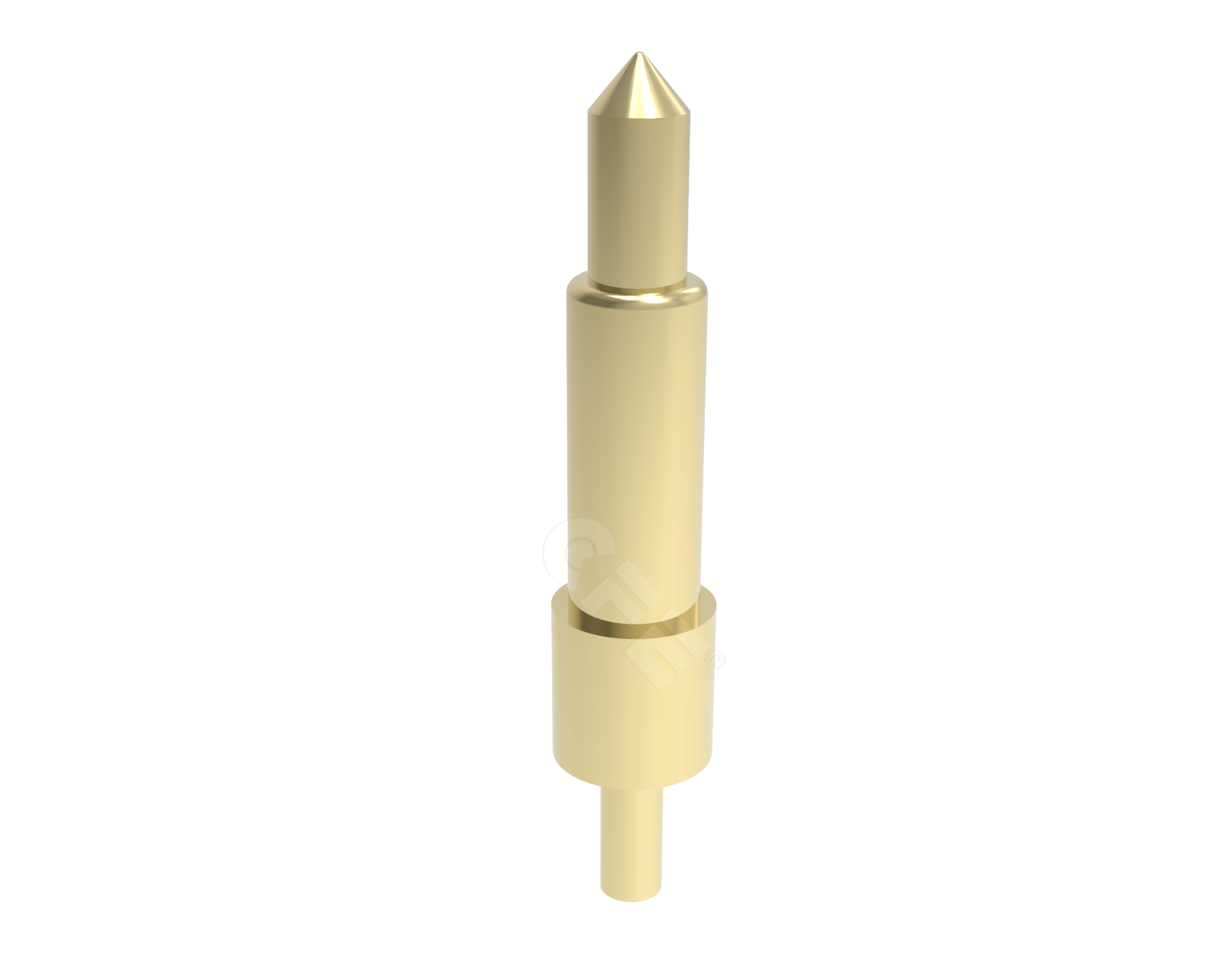

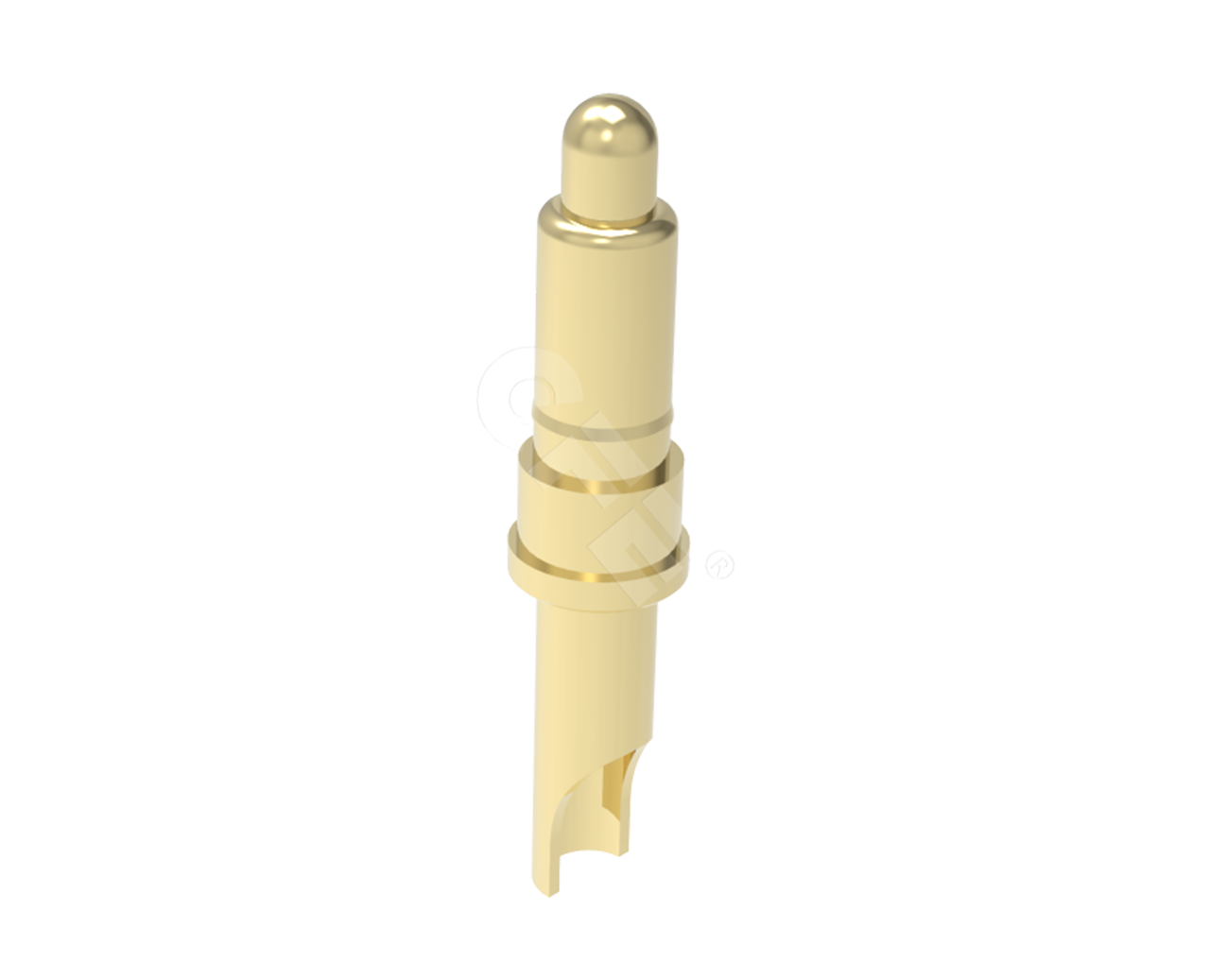

| SMT/SMD | DIP | Right angle | Double head | Solder cup | Screw thread |