Pogo Pin sockets are a key element in the development and testing of semiconductor products. Different types of sockets provide specific electrical and mechanical parameters for specific steps in the product testing process. In high-performance sockets, Pogo Pin socket is still 90% of the application’s contact. However, for high-speed serial links and emerging RF (RF) applications, engineers must replace the familiar Pogo Pin socket with more external contactors to ensure signal integrity and reliable performance.

Pogo Pin Socket Classes

Throughout the product development process, the electrical and mechanical properties required to support the various test requirements vary widely. For example, aging sockets tend to be used in applications where the test signal is quite low (usually several kHz). Aging test time is long and the temperature is high, usually 125 ℃. The goal in this application is to detect device failure based on extended thermal stress for 24-72 hours without the need to disassemble the device. In order to produce a statistically well-established reliability model, it is necessary to shield a large number of devices and typically require up to 10,000 sockets. Thus, due to a number of economic reasons, the aged outlet has a stamping contact and is designed to capture the device into the receptacle without the use of a clamshell cap.

|

|

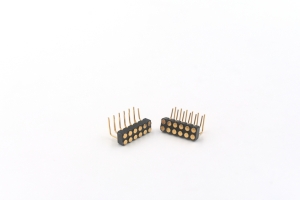

| [FP420-1110-A06100A] 6 pin female right angle spring pin connector | [FP420-1110-A06100A] 6 pin female right angle spring pin connector |

Advantages

- High Durability

- Easily adapted to customer needs

- Spring strength can be measured and regulated

- Space-saving in comparison with plugs

- Ultra-small Pitch

- SMD-Assembly

- Excellent performance and specially suitable for High-Frequency Application

- RoHs Compliant and Halogen-free

Conclusion

Although the Pogo Pin socket is the first choice for most applications, the frontier application makes test requirements beyond the functionality of the traditional Pogo Pin socket solution. High performance test sockets can support the performance requirements of emerging test applications by moving to elastomers and new contact methods, such as highly conductive polymers and new solid lines.