Spring Loaded Locating Pin Assembly

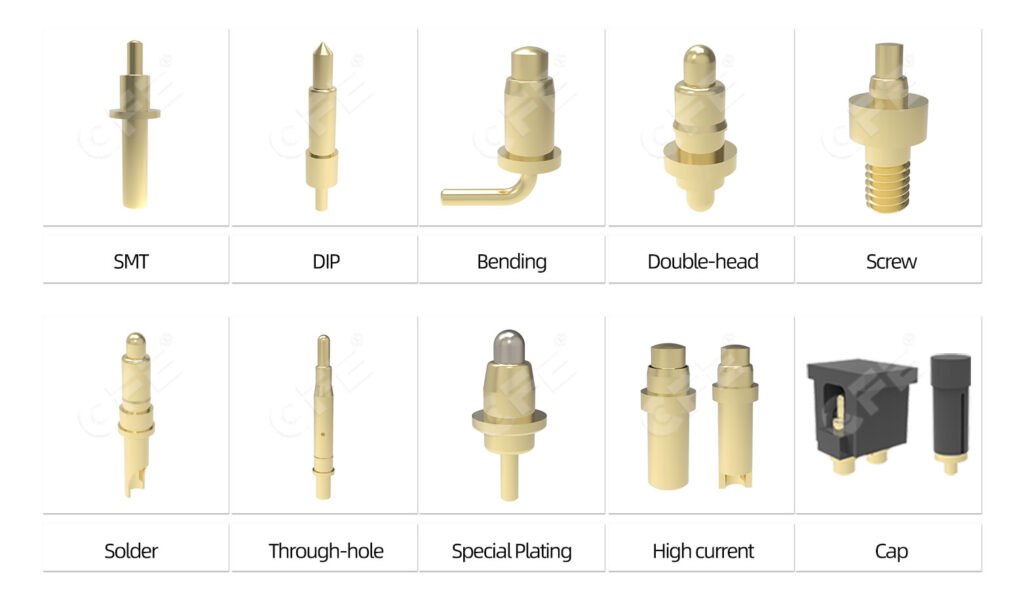

We offer a wide range of different spring contacts or battery charging contacts . For tabular overview , see the respective product type . Customer-specific developments are possible .

Spring Loaded Locating Pin Assembly Construction

The Pogo Pin consists of three parts: the plunger (piston), the spring and the bucket.

The Pogo Pin connector consists of multiple Pogo pins (same type) in the plastic housing. There are many standard Pogo Pin connectors available. Special customer design of the Pogo Pin connector can be changed by changing the pitch, pin count and shell size to achieve. The flexible pin design allows a variety of SMD circuit board configurations.

Manufacturing of Spring Loaded Locating Pin Assembly

To ensure 100% contact of the piston with the pin sleeve, use the offset design. In this design, the piston is chamfered at its end at an angle of up to 18 ° and is inserted into the pen cover. Therefore, when the spring contact pin is actuated, ensure that the piston is in contact with 100% of the pin sleeve. This will significantly reduce the signal interference due to vibration. The bias design is suitable for almost all spring contact probes with a length of 3.5 mm. For smaller structures, the so-called post-drill design is applied. In order to achieve the desired customer-specific spring force, the spring used in this design is longer than the hollow piston.

The requirements for current carrying capacity (> 3A) are higher and the offset design is complemented by the 4P design. When the piston and pin sleeve spring contact pins are not properly connected at high currents due to insufficient lateral forces, they may cause strong heating of the compression springs. In order to prevent this, the first three parts of the spring contact pin (piston, compression spring and sleeve) are designed by the fourth component of the 4P by stainless steel balls. The ball is integrated between the piston and the compression spring. The result is an increased spring force, which results in a guaranteed contact between the piston and the sleeve. The current flow is redirected to the sleeve on the ball.