Magnetic connector, also known as pogo pin magnetic connector. It is an upgrade based on the pogo pin connector by adding positive and negative magnet components. Implemented the function of automatic adsorption when the male and female ends are close to each other. The magnetic connector simplifies the charging and connection process.

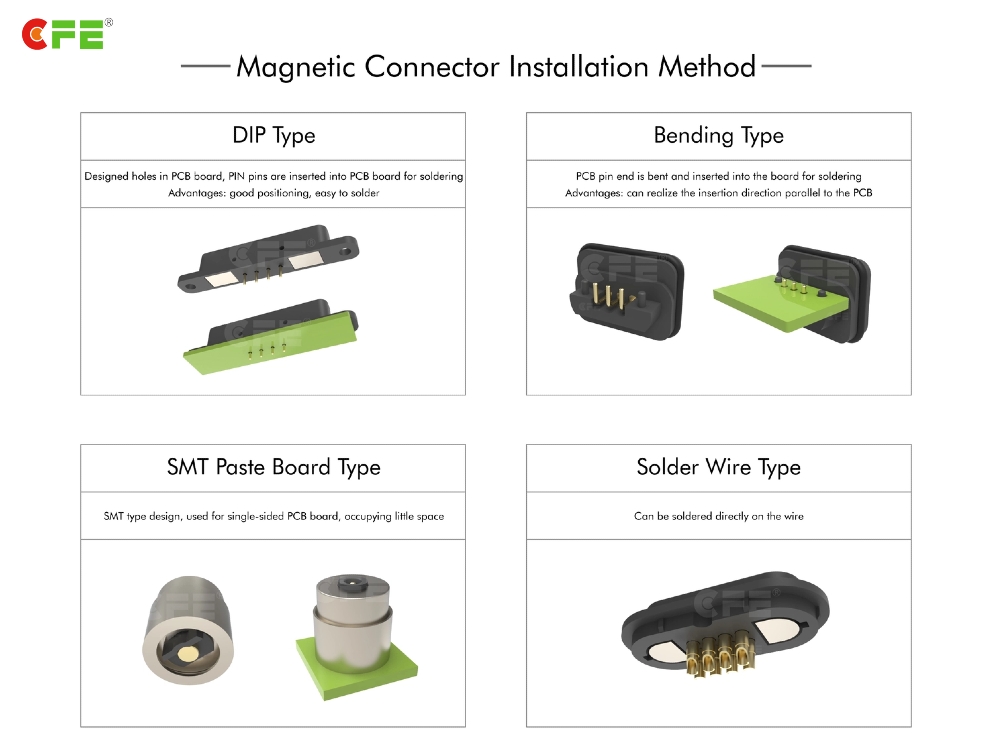

The installation method of the magnetic connector is closely related to the structure of the magnetic connector. Different structure types, its installation method and PCB will also be different. Today, CFE corporation will analyze the installation method of pogo pin magnetic connector in detail. Take the DIP structure as an example. During the installation process of the DIP pogo pin magnetic connector and the PCB, the PCB needs to have pre-designed hole positions. And then insert the DIP pins into the PCB board for soldering. The advantage of this structure is good positioning and convenient welding. In addition to DIP structure, pogo pin magnetic connectors also have bending type, SMT paste board type, solder wire type and other structures. The installation method is as shown in the figure.

Whether considering the convenience of installation, stability of use or ease of operation, pogo pin magnetic connectors have demonstrated excellent performance. Therefore, it is gradually favored by more and more manufacturers.

CFE has been operating for 14 years+ mainly engaged in pogo pin, magnetic connectors, customized magnetic products and module products. Pogo pin magnetic solutions can ensure safe current transmission and signal data storage of customer products. At the same time, the pogo pin magnetic connector ensures simple connection for charging, high product safety and excellent waterproof performance. The CFE pogo pin magnetic solution maximizes the value of the end product and allows the product to bring a better experience to users. CFE also provides precision turning pin, precision injection molding parts, magnetic charging cables, and precision module customization , Automotive high-current connectors, EMS services for medical monitoring equipment, design, development and manufacture of intelligent production and testing equipment.