A pogo pin connector is a special type of connector. Any connection system must transfer electric energy from one system to another system through the connection part. At this time, the contact at the connection part is often the main node of electric energy transmission. Current products are more complex and require increasingly higher reliability of connection parts. If a few of the thousands of connection points have poor contact or are disconnected causing the entire system to not work properly, the consequences will be extremely serious.

The conductor connections are connected mechanically, and the way electrical energy passes is electrical contact. The connection between the pogo pin and the mating end of the pogo pin connector is a typical form of electrical contact.

Moreover, the pogo pin connector is a detachable contact method with long life and convenient docking. Contact points tend to arc when breaking or closing a circuit. The temperature of the arc is very high, much higher than the melting point or boiling point of general metal materials. Even if the arc exists for a short time, the surface of the contact point will melt and vaporize, causing the loss of contact point material. The presence of arcing prolongs the duration of the faulty circuit at the junction. And the high temperature generated will melt or vaporize the surface of the contact point and burn out the insulating material.

How is the arc generated?

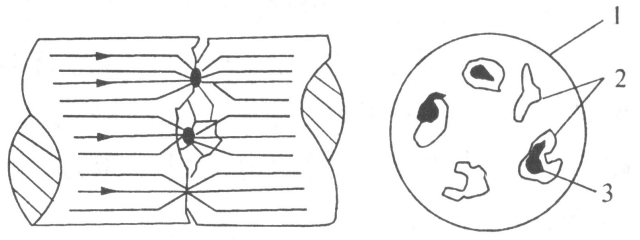

First look at the contact surface. Any metal surface that looks very smooth to the naked eye is actually rough. When two metal surfaces come into contact with each other, only a few protruding points (small contact surfaces) actually make contact. Only a small portion of the metal or quasi-metal contacts can conduct electricity. When current passes through these small conductive spots, the current lines must shrink. The current line shrinks, the current path flowing near the conductive spot grows, the effective conductive cross-section decreases, and the resistance value increases accordingly. (As shown below)

Real physical contact situation

The contact and separation of spring pin connectors are divided into two processes: making and breaking.

Making process: Due to the gap during the needle closing process, gas breakdown occurs, short-term arc discharge occurs, and eventually electrical erosion occurs. At the same time, the male and female joints collide and cause mechanical wear. The needle impact sometimes causes the pin to bounce, making the arcing time unsteady and prolonged. When the contact point is closed, a large impact current will be generated, causing the arc discharge to act on the electrode multiple times in a short period of time, forming the so-called “kinetic fusion welding”.

Breaking process: When breaking the circuit, arc discharge will occur between the pins. The arc heat generated acts on the surface of the needle, and complex physical and metallurgical processes occur on the surface of the needle, such as material phase change, material erosion, material transfer, molten pool splash, etc. The result of these physical metallurgical processes is to change the composition and morphology of the needle surface and increase the contact resistance between contacts. At the same time, the needle material is eroded and worn away, eventually leading to electrical contact failure.

Pogo pin magnetic connector solution provider

CFE has currently developed specific solutions for large current transmission. The current can reach from 1A to 60A, and it has also been widely used in various industries. Especially in the fields of electronic cigarettes, tablet computers, printers, etc., it is necessary to realize the function of small size and high current in a short time. In addition, CFE also provides customers with one-stop customized pogo pin magnetic charging solutions. Provide innovative solutions for customer products to achieve product upgrades and technological innovations.